OxyDoser™ PUREair

Micro-Nano Bubble Generator

Hydroponic and Actively Aerated Compost Tea Bubble Generator

Industrial and Military Bubble Generator

CLICK HERE to BUY NOW in the United States

CLICK HERE to BUY NOW Outside of the United States

NOW CONVERTABLE BETWEEN:

HIGH PRESSURE MODE (HPM) - Micro Nano Bubbles w/ 50 PSI 400-1500 GPM water pump, and

LOW PRESSURE MODE (LPM) - Liquid Thin Film w/ low PSI 250-400 GPM water pump

The OxyDoser™ PUREair produces bubbles and Oxygen Saturation using two different techniques at the same time while using only the power of a low wattage Hydroponic Water Pump. The OxyDoser™ PUREair can also be converted from low pressure to high pressure to make smaller bubbles and can be used with either normal air or compressed Oxygen.

For Low Pressure Mode (LPM) use. The device is plumbed in line with a 160-250 gph pump and a standard 1/4" air line is attached to the air nozzle. There are no moving parts. In low pressure mode this device can saturate 100-200 gallons of fluid. Multiple OxyDoser™ PUREair devices can be used for larger volumes or you can use in high pressure mode. See low pressure operation below.

When the pump is started, water is forced into the OxyDoser™ PUREair's two patent pending nozzles, one at each end. Air is sucked into the air line via the vaccuum created by the swirling motion of the water inside the OxyDoser™ PUREair. One end produces MicroBubbles and the other produces Liquid Film. Both of these mixture technologies ease the transfer of gas in and out of the water. Easing this transfer matters, this is how your hydroponic fluid gets Oxygenated. Air Bubbles from an Air Stone can do this, the OxyDoser™ PUREair can do it much better.

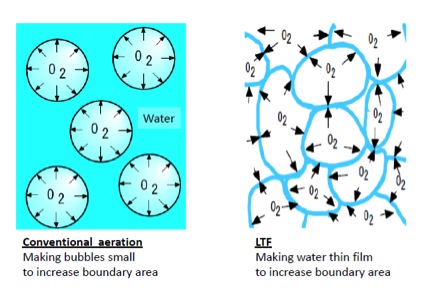

The difference between the bubble types can be seen in the following diagram. In Low Pressure Mode (LPM), the OxyDoser will force all of the water or fluid to go through the Liquid Thin Film (LTF) process. You know liquid thin film as the "foam" on top of a mug of beer or as the "bubbles" you may have blown with a wand as a child. LTF is actually a thin film of fluid wrapped around a pocket of gas....as opposed to a submerged bubble which is a pocket of gas in a body of fluid as is used in conventional aeration (as well as HPM OxyDoser Use)

For High Pressure Mode (HPM). The device is plumbed in line with a 50 psi pump and the "mushroom" thin film top is removed. A standard 1/4" air line is attached to the air nozzle which can draw in air or attached to compressed Oxygen but in either case you will have to RESTRICT the flow to about 1/4 liter per minute (LPM) as the OxyDoser is extremely efficient at using gas (meaning you get more bubbles with less gas) as you will not have as much gas forming bubbles that quickly rise to the surface and pop. In High Pressure Mode (HPM), the device can saturate 1000's of gallons of fluid. There are no moving parts all energy and equipment motion is derrived from the water pump - no air pump is used while in HPM. See high pressure operation below.

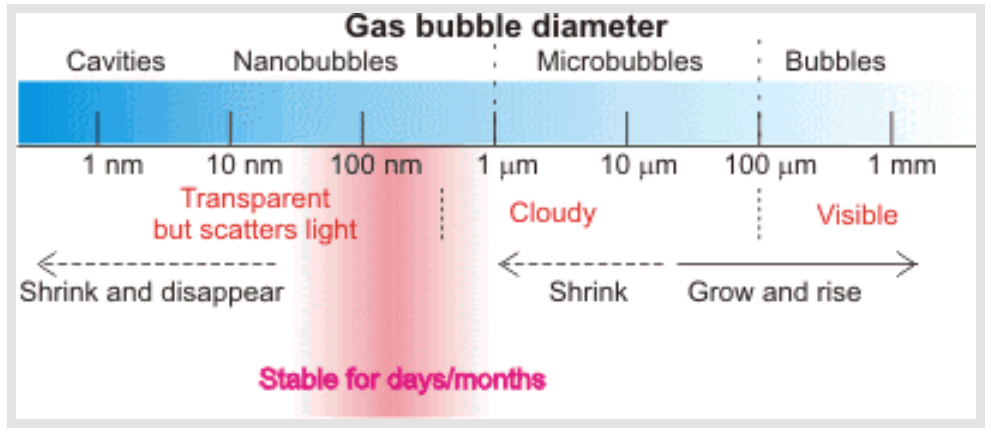

Bubble Size Overview

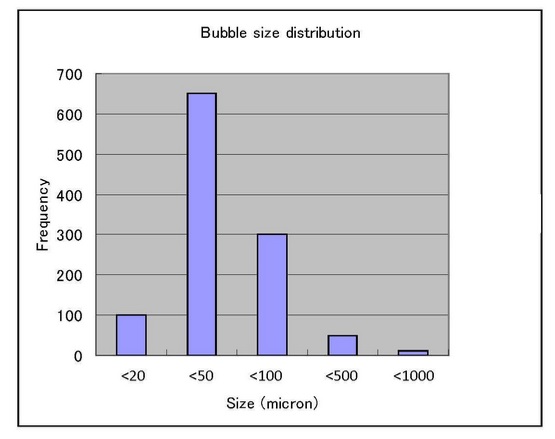

Typical Bubble Size Frequence Diagram

Microbubbles and Nanobubbles are simply small bubbles. Micro Bubbles and Nano Bubbles are good for plants for two reasons:

1. MicroBubbles have more Surface Area for a given volume of air vs. large standard Air Stone bubbles. This greater Surface Area increases the amount of Oxygen that can be transfered into the Water before the bubble is gone. MicroBubbles also stay in suspension longer before they pop, also allowing for increased saturation.

2. MicroBubbles have an Ionic Charge. This Ionic Charge allows for Ionic Bonding with Charged Nutrients, thus allowing for better utilization and transfer of your N-P-K and MicroNutrients.

Nutrient Film is really water wrapped around gas, in stead of gas in water. You see nutrient film when you see water boil or when you see soap foam. The bulbed housing on the OxyDoser Air forces all of the fluid that escapes from that and of the unit to go through the Liquid Film process. This Liquid Film has increadibly high Surface Area relative to volume of fluid and is even better at producing Oxygen saturation than MicroBubbles, but does not produce Bubbles with an Ionic Charge. This is why we coupled the two halves into one great oxygen producing device!

The OxyDoser™ Air gives you both Bubble and Gas Saturation Technologies in one unit with the following benefits vs. Air Stones:

1. Increased Oxygen Saturation resulting in more root growth, thus increasing Yeilds.

2. Increased Oxygen Saturation resulting in less pathogens such as root rot.

3. Production of MicroBubbles with an Ionic Charge which eases Nutrient Transfer to the roots resulting lower Nutrient Concentrations.

4. Large Capacity - approximately 200 gallons of full Oxygen Saturation can be achieved with one unit. Multiple units can be used for larger volumes or you could consider the OxyDoser™ Pure.

5. Displacement of other contaminate gases present in the Water such as CO2 from the Grow Room. CO2 is for the leaves, not the roots.

6. 85% less heat generated from the assoicated 250 gph water pump vs. a 110 lph air pump. This reduces the burden on fans and cooling devices.

7. Save approximately $150/year using a 250 gph water pump vs. a 110 lph air pump. The unit will pay for itself in less than 2 years on power consumption alone.

8. No Air Compressor Noise, you only hear water flowing.

9. Flowing water from device serves to mix and evenly distribute Oxygen Saturated Fluid.

10. Way cooler to talk about at Cocktail Parties.

CLICK HERE to BUY NOW in the United States

CLICK HERE to BUY NOW Outside of the United States